SGS Quay Pharma – Pharmaceutical

SGS Quay Pharma – Pharmaceutical

Location

UK – Deeside, North Wales; USA – New Hampshire & Massachusetts

Problem

Safe way of preventing needle sticks needed on a repeating manual task

Result

Product designed and manufactured that has meant no needle stick injuries have occurred throughout production.

Background

SGS Quay Pharma are a world leading Contract Development Manufacturing Organisation (CDMO). They specialise in the development of innovative new entities for biotech companies, globally.

Why choose Addition?

End-to-end design and additive manufacturing means we understand your problem and deliver the solution. Before committing to design work, we will create a bespoke design brief so that you can be sure of what we will deliver before committing. We seek to ensure that every solution strikes a balance between pragmatism and innovation – our designs create a competitive advantage for our customers.

What was the problem?

SGS Quay Pharma had successfully secured a high-value contract to manufacture a dosage of a new liquid form pharmaceutical. The production process required the extraction and mixing of very small amounts of liquids which themselves are in sealed vials. To achieve this, several steps of extraction and transfer using 1ml and 0.3ml syringes take place in a highly controlled GMP cleanroom facility. To overcome the intricacies of this process, SGS had identified best practices, but the process was not effcient and needle stick injuries had been identified as a likely risk. A solution was needed to ensure that the task could be repeated accurately, efficiently, and safely.

What did we do?

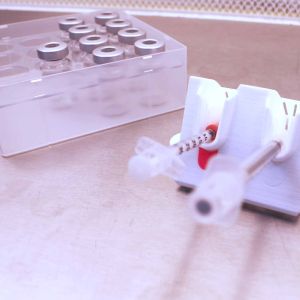

Addition worked with SGS Quay Pharma to develop two bespoke devices which addressed the issues of accurately placing and controlling the syringe whilst ensuring the operator’s safety.

The first device holds the syringe in the correct orientation and depth for effective extraction from the 5ml vial. It includes a raised lip area which acts as a guard to prevent needle stick injury and is adjustable for different operators – locking into position when set up to ensure consistency of the process.

The second device prevents needle stick injuries whilst placing the syringe cap back onto the syringes which occurs several times through the process. It locks itself to the steel bench using sucker pads and retains the two capped needles, allowing the needle to be separated and placed back into the cap with one hand, preventing any kind of operation which can lead to needle stick injury.

Once the devices were approved, Addition manufactured batches from a fully compliant engineering grade polymer using their in-house industrial 3D printer all within the space of 4 weeks to meet the start of production for SGS Quay Pharma.

Product designed and manufactured that has meant no needle stick injuries have occurred throughout production

Gallery

Addition was quick to understand what we needed and delivered a great product which kept our stay safe and ensured we could deliver the quality our customers expect. When excellent design practice and 3D printing is used like this, we can all see the benefits. We look forward to working with Addition again as we continue to expand our capabilities and customers.

Russ Pursell, Head of Manufacturing, SGS Quay Pharma