Opinion piece published in the March 2023 edition of Process & Control Today magazine

In the post-pandemic world, where the shockwaves of Brexit continue to ripple through the supply chain, fast-paced innovation within the 3D printing sector is helping the UK’s pharmaceutical industry to keep moving, as Tom Fripp, director at Sheffield-based 3D printing firm – Addition Design, explains:

It’s no secret that supply chains around the globe are feeling the strain. Turbulent trading conditions caused by a whole host of unprecedented challenges facing society at present mean most industries are needing to adapt fast and seek out new ways to overcome the hurdles of doing business in today’s markets.

The UK’s pharmaceutical industry is no exception.

On the back of a perfect storm which saw both the Covid-19 pandemic and Brexit, manufacturers within the sector are reporting lead times for format and change parts of up to 15 weeks, making production line downtime an incredibly expensive and often unaffordable occurrence.

However, innovation within the 3D printing sector is meaning that increasingly, machine lines don’t have to grind to a halt.

With the capability to design and reverse engineer like-for-like components here in the UK, using raw materials sourced from within the country, we’ve been able to cut machine line downtime from 15 weeks to just five to seven days in some cases.

It’s a huge impact, considering the cost of downtime in a high value sector such as pharmaceutical can be as much as £15,000 a day, and it makes the business case for industrial 3D printing a very promising one indeed.

Material gains

Advances in 3D print systems are opening up a whole world of opportunity and enabling companies such as ours to produce the often large and robust change and format parts required by pharma, as well as to utilise higher performing materials capable of replacing metal parts and the Polyoxymethylene (POM) typically used by OEMs.

Nylon is very good at replacing POM-based components like for like, and we’ve just invested more than £100,000 in a new Stratasys F370®CR FDM® Composite Printer, which enables us to print carbon fibre reinforced components.

Nylon is very good at replacing POM-based components like for like, and we’ve just invested more than £100,000 in a new Stratasys F370®CR FDM® Composite Printer, which enables us to print carbon fibre reinforced components.

Both of these materials are much more lightweight than their more traditionally manufactured counterparts, meaning reduced machine wear and a longer lifespan for production equipment, saving maintenance and replacement costs in the future.

Utilising these materials also means organisation’s engineering teams can input into the design process. After all, the highly-skilled engineers who set up pharmaceutical production lines know their machines inside out and are often able to make design suggestions that not only replicate but further enhance the finished component, sometimes incorporating multiple functions in one.

Navigating regulation and IP

Of course, when it comes to replicating parts and manufacturing components for existing equipment, questions are often asked around how 3D printing can comply with necessary pharmaceutical regulation and navigate the issue of intellectual property (IP).

Of course, when it comes to replicating parts and manufacturing components for existing equipment, questions are often asked around how 3D printing can comply with necessary pharmaceutical regulation and navigate the issue of intellectual property (IP).

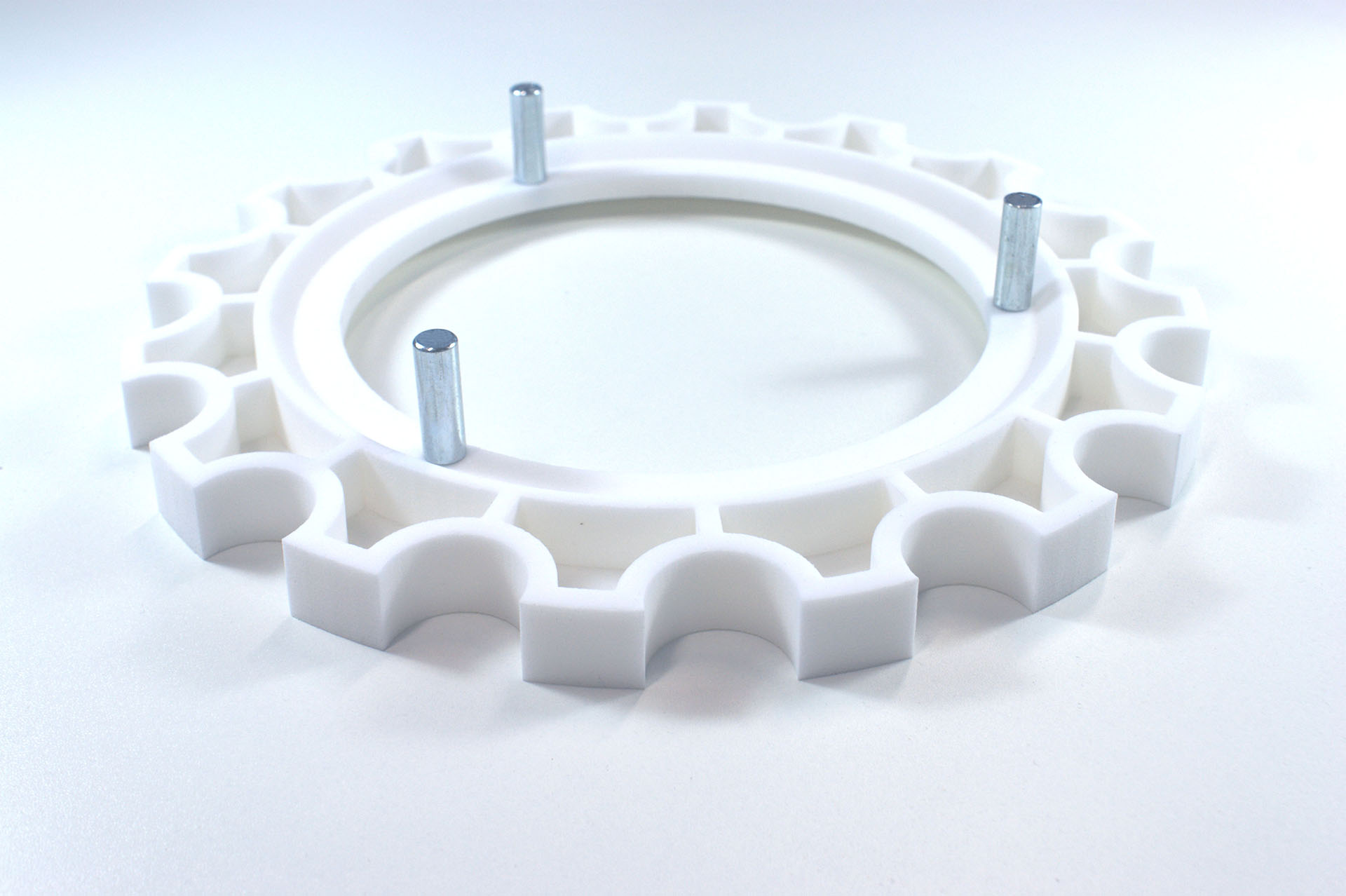

On the latter, it is rarely an issue. This is because more often than not, companies are seeking replacement parts to fulfil functions that are not core to the OEM’s design and therefore exempt from IP ownership. For example, star wheels or guide parts.

Equally, the machine for which the replacement part is being made for is usually out of warranty, too, with 3D printing increasingly turned to as a way of extending the usability of older production line equipment.

With regards to regulatory requirements, we also find that compliance issues are few and far between as the accuracy of 3D printing means components are often like-for-like in their size and shape and all the materials we use have full traceability, thanks to our own quality management procedures.

However, whether it’s determining IP restrictions or ensuring compliance requirements are met, working closely with a clients’ quality management team remains a vital part of the industrial 3D printing process.

Any duplication project should start with a site visit and a data capture exercise to review the machine and the components that are needed before the CAD process to replicate them even begins. From this, certificates of conformity can be produced after production and quality assurance clarity and detail provided where necessary.

Future thinking

While it’s been around for a while now industrial 3D printing is evolving fast and, on the back of the pandemic and Brexit, more and more industries are awakening to the commercial benefits it has to offer.

While it’s been around for a while now industrial 3D printing is evolving fast and, on the back of the pandemic and Brexit, more and more industries are awakening to the commercial benefits it has to offer.

From the rapid turnaround time for replicating critical components, to the exciting advances being made in printing technology that mean materials such as carbon fibre can be used to produce high performance parts, 3D printing is truly asserting its place at the industrial engineering table.

And, for an industry as heavily regulated and as high-worth as the pharmaceutical sector, it’s proving to be a lifeline.

Machine downtime can cost pharma companies hundreds of thousands of pounds, thanks to ever increasing supply chain delays on the continent.

Reverse engineering using pioneering 3D printing techniques eliminates this, cutting lead times, improving lifespan and reducing costs.

And, at such a challenging time for industry, that’s exactly what the doctor ordered.

You can view the online edition of Process & Control Today here

Click on the image below to download the PDF of the article.